Automatic HEPA Filter Paper Pre-slitting Machine With CE Certification

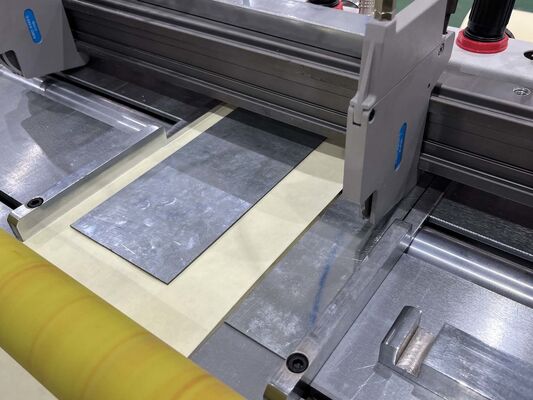

This production line consists of an auto paper de-coiler, pre-slitting conveyor, marker, automatic counter, and filter paper pleating machine equipped with a pre-heater and monitor. It features precise frequency-controlled slitting, infrared synchronization, computer-controlled marking, and stable high-speed pleating with upper/lower alternating blades. After marking, the filter paper is automatically pleated and pre-heated.

The machine is also suitable for folding iron wire fabric, non-woven fabrics, and multi-layer hydraulic filter materials. Customizable machine width and pleating height are available, including optional “M-type” pleating.

Product Specifications

| Item |

Specificatiom |

| Speed |

0.5m/min~12m/min (adjustable) |

| Adjustable width |

30~1100mm |

| Power supply |

220V/50Hz |

| Motor power |

0.75kw |

| Working air pressure |

0.6MPa |

| Machine weight |

350kg |

| Machine size |

1500*1300*1100 mm (L*W*H) |

Main Features

1. The pre-slitting machine can accurately and freely adjust the cutting dimensions through frequency converter speed regulation and cylinder blades in different filter sizes. It is simple operated but smooth and effective. After slitting the paper, the conveyor for feeding the filter paper runs in synchronization with the marking machine by equipping the infrared monitoring system.

2. The marking machine can mark in different pleat sizes, the marking distance can be set freely by the computer screen, and accurately and accurately by automatically adjusting the blades distance.

3. The pleater uses upper and lower blades to alternately finish the folding, then different pleating heights are acquired evenly and accurately by automatically adjusting the blades distance.

4. After marking, the filter paper will be pleated and pre-heated.

5. The machine is also suitable for folding the iron wire fabric and non-woven fabric of the hydraulic filter, even the multi layers folding.

Product Advantages

- Fully automated workflow from slitting to pleating

- Infrared synchronization ensures consistent marking and slitting

- Precision marking and pleating with automatic blade adjustment

- Supports wide pleating ranges (8–55 mm)

- Excellent for paper, wire mesh, and non-woven folding

- Stable performance for high-volume industrial production

- Can pleat “M-type” shapes (custom option)

- Customizable width and pleat heights for various filter industries

Applications

- Automotive air conditioning filters

- Cabin air filters

- Industrial and HVAC filters

- Household air purifier filters

- Nonwoven and pleated filter frames

- Any filter requiring precise four-side edge strip removal

Ideal for filtration processing factories, air filter assembly lines, and precision finishing workshops.

Company Profile

Established in 2011, Bengbu Tongchen Automation Technology Equipment CO.,LTD is a specialized firm that integrates research, development, manufacturing, marketing and after-sales service for filtration equipment manufacturing equipment. Our primary product offerings encompass a range of advanced machinery, including fully automated reciprocating paper folding production lines, fully automated PP intermittent glue injection and wave reception production lines, and fully automated paper frame gluing production lines. For more information or to schedule a demonstration, please contact us. We are committed to providing tailored solutions that meet the unique needs of our clients.

Production Packaging

Frequently Asked Questions

Can you give me a discount price?

Discounts depend on order volume. Larger quantities qualify for greater discounts.

How do you guarantee your quality?

Our experienced workers and technical staff ensure product quality. All products undergo thorough inspection by quality control personnel before shipment.

How about your after-sales service?

We provide professional technical support through our dedicated service team, available for online guidance and troubleshooting.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!