Bengbu Tongchen Automation Technology Equipment Co., Ltd.

A Leading Innovator in Filter Manufacturing Automation

As a professional developer, designer, and manufacturer of filter production equipment, Bengbu Tongchen is headquartered in Bengbu—known as the "Pearl City," a vital

transportation hub, cultural heritage city, and industrial center in China. Specializing in advanced automation solutions, our core portfolio includes:

Paper pleating systems

Rotary machinery

Diesel engine filter production lines

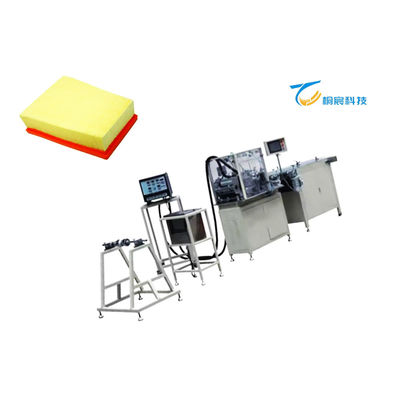

Large air filter manufacturing equipment

Partitioned/partitionless filter production lines for purification industries

High-precision pleating machines

Partitionless glass fiber strip production lines

Driven by technological innovation, we continuously engineer advanced, efficient, and reliable equipment to meet evolving industry demands. Our solutions align with global standards while leading domestic trends, empowering customers in medical, electronics, semiconductor, and industrial sectors to achieve standardized, high-volume production.

Quality and service are the cornerstones of our philosophy. By integrating cutting-edge technology with rigorous quality control, we help clients enhance brand competitiveness worldwide. As your trusted partner in China, Tongchen Technology is committed to delivering tailored mechanical solutions and fostering long-term collaborative growth.

Contact us today to explore how our automation expertise can elevate your filter manufacturing capabilities.

Our Advantages:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!