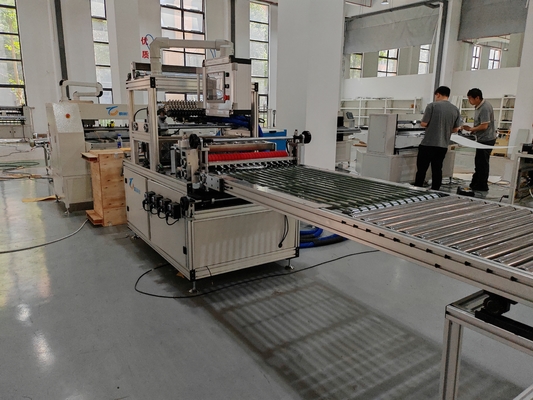

PP Gluing Machine

Product Description:

This gluing machine has precise glue application functionality, capable of evenly spreading adhesive on the surface of PP material. The operation interface is simple, making it convenient for users to set glue application parameters. It features an automatic sensing device that adjusts the glue application range according to the size of the material.Equipped with a stable transmission system, ensuring smooth movement of PP material during the adhesive application process. Adjustable adhesive thickness settings meet different processing requirements. The human-machine interface is user-friendly, parameter settings are simple, and it is easy to operate and maintain.Improve work efficiency and product quality to make the gluing operation more effortless and efficient.

Product Paramenters

| Machine Name |

PP Gluing Machine |

| Model |

AUTO700 |

| Max width |

<=700 |

| Pleating depth |

30-300mm |

| Pleating speed |

15-20pleats/min |

| Pre-heat-power |

1kw |

| Power voltage |

220/380V/50HZ |

| Raw material coil diameter |

<=800mm |

Our Advantages

Details Images

Certifications

Company Profile

About us :Established in 2011,Bengbu Tongchen Automation Technology Equipment CO.,

LTD, is a specialized firm that integrates research, development, manufacturing, marketing

and after-sales service for filtration equipment manufacturing equipment. Our primary pro-

duct offerings encompass a range of advanced machinery, including but not limited to

fully automated reciprocating paper folding production lines, fully automated PP intermittent

glue injection and wave reception production lines, fully automated paper frame gluing

production lines.

Product packaging

FAQ

Can you give me a discount price?

It is depending on the volume. The larger the volume is, the more discount you can enjoy.

How do you guarantee your quality ?

Our workers and technical employees are with many years experiences to ensure the

products are good. After production finished,check will be made by quality inspector.

How about your after-sales service?

We have a professional technical service team to provide online guidance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!