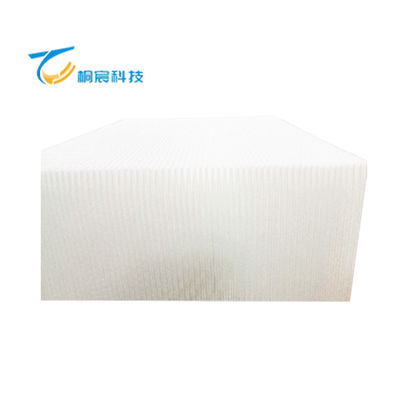

300-fold Height Fully Automatic Papermaking And Gluing Production Line Without Partitions

Product Description:

The Filter Production Equipment is a state-of-the-art machinery designed for the efficient production of Heavy Equipment Filters, Construction Equipment Filters, and Industrial Equipment Filters. This advanced equipment offers a wide range of features and benefits, making it an essential tool for filter manufacturing companies.

One of the primary advantages of this Filter Production Equipment is its high efficiency automatic working system. With automatic functions, this equipment streamlines the production process, saving time and labor costs while ensuring consistent quality output. The automatic working system allows for a seamless operation, making it ideal for high-volume filter production.

Equipped with a durable pleating blade made of tungsten carbide, this equipment ensures precise and clean pleating of filter materials. Tungsten carbide is known for its hardness and wear resistance, providing longevity and reliability to the pleating process. This high-quality blade contributes to the overall efficiency and accuracy of the equipment.

The Filter Production Equipment is powered by a robust motor with a power rating of 22kw. This powerful motor drives the equipment's operations, delivering the necessary force and speed for efficient production. With a motor power of 22kw, the equipment can handle heavy-duty tasks and maintain high performance levels consistently.

Operating at a frequency of 50Hz, this equipment is designed to meet standard industrial power requirements. The 50Hz frequency ensures compatibility with common power supplies, making it suitable for various manufacturing environments. This frequency setting optimizes the equipment's performance and energy efficiency during operation.

With a power consumption of 350, the Filter Production Equipment offers an optimal balance between performance and energy efficiency. The power rating of 350 allows the equipment to operate effectively while minimizing energy costs, making it a cost-effective solution for filter production facilities. The equipment's power efficiency contributes to long-term savings and sustainability.

Features:

Product Name: Filter Production Equipment

Motor Power: 22kw

Production Speed: 2~15m/min

Voltage: 380V

Max Web Width: 700mm

Key Selling Points: High Productivity

Technical Parameters:

| Key Selling Points |

High Productivity |

| Frequency |

50Hz |

| Pleating Blade |

Tungsten Carbide |

| Production Speed |

2~15m/min |

| Warranty |

1 Year |

| Voltage |

380V |

| Power Source |

Electric |

| Motor Power |

22kw |

| Dimensions |

7000×1700×1800mm(L×W×H) |

| Advantage |

High Efficiency Automatic Working |

Applications:

The pleat production line, with its high-precision folding, intelligent glue control and servo collaboration technology, deeply embeds multiple filtration and separation scenarios in various fields. In the field of air purification, we customize HEPA non-woven filter paper for household and commercial air purifiers and fresh air systems. Through precise folding and uniform corrugations, it enhances the adaptability of dust holding capacity and wind speed, and efficiently intercepts particulate matter. In the automotive industry, it supports the manufacturing of air conditioning filter elements (for purifying exhaust gases and pollen) and engine intake filter paper (for filtering impurities), ensuring the consistency of corrugations through servo synchronization and enhancing the stability of filtration. In medical Settings, services are provided for sterile environments such as operating room purification and biosafety cabinets, and the aseptic folding process is adopted to avoid secondary pollution. The industrial end is covered with dust removal (welding fume), oil filtration (hydraulic oil), etc. The high-precision folding meets the requirements of pressure difference resistance and long service life. In the field of environmental protection, it helps with the adsorption of waste gas (VOCs) and water treatment (pleated membrane modules), promoting the separation of pollutants by increasing the filtration area. Its core value lies in driving the efficient production of filter materials through technological breakthroughs, providing underlying manufacturing support for the purification and precision processes in various fields.

Company Introduction:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!